Why Heat-to-Fuel?

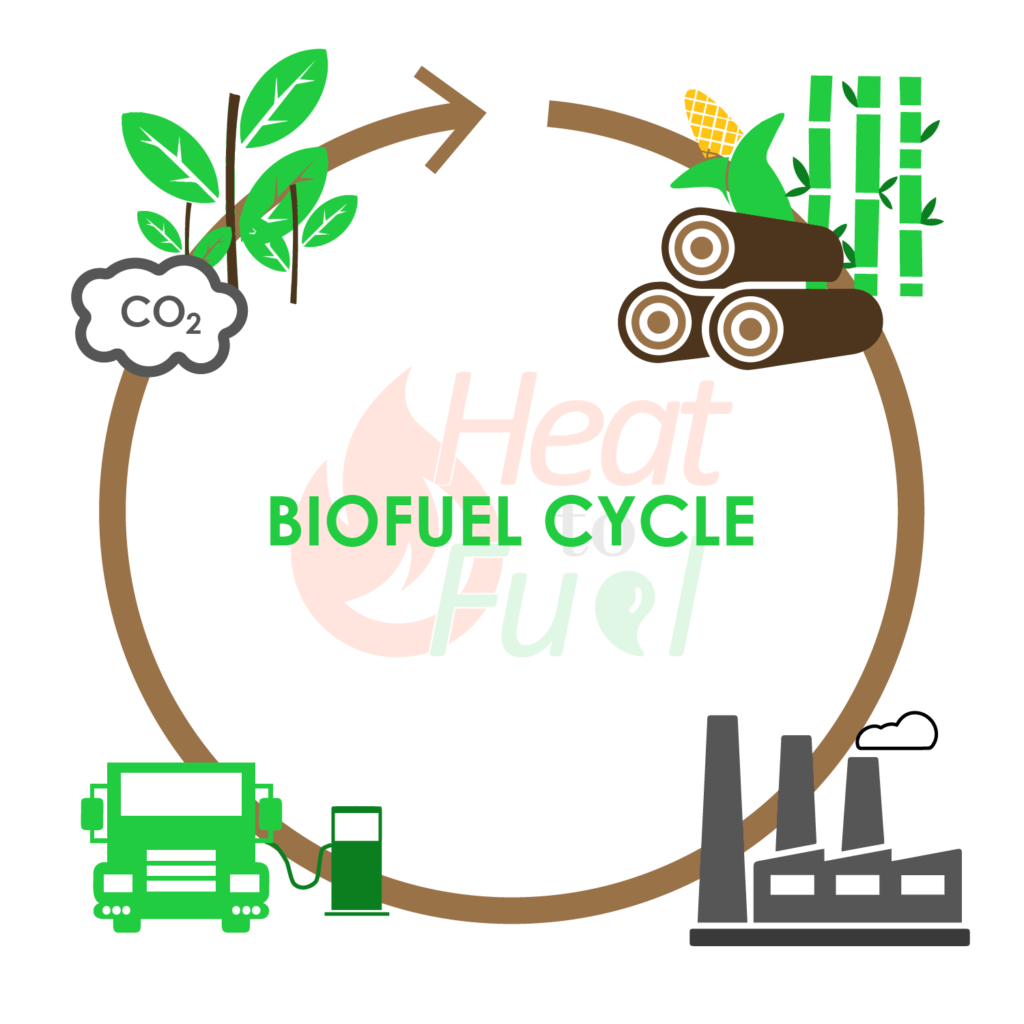

Transportation fuels corresponded in 2013 to 31.6% of the final energy consumption in Europe. The source of this energy depends to a large extent on fossil fuels imports. Diesel and kerosene represent, and will remain, two major fuels for heavy trucks and air transportation sectors, respectively. Indeed, the energy density of both fuels, about 35-38 MJ/L, is unparalleled by other alternative solutions such as batteries, hydrogen, methane and DME. Decarbonised production of additive substitutes for fuels and diesel and kerosene (biofuels) as alternative to fossil fuels becomes relevant for reducing carbon emissions of both transport sectors.

Europe should grasp the opportunity and gain its leading role in providing efficient technologies and processes for decarbonised fuels for the transport sector of heavy trucks and aviation. The achievement of this challenge must be conducted through a synergic collaboration between universities, R&D institutes, and industry. In that perspective, Heat-to-Fuel will investigate and validate an advanced concept integrating dry and wet biomass residues processing, thus exploiting the huge potential of Carbon conversion efficiency improvement arising from this configuration.

Dry biomass and organic waste conversion through gasification routes is characterized by large heat excess, which can be conveniently exploited by wet biomass and waste conversion routes. The combination of those routes is embedded within Heat-to-Fuel spirit, aiming at reaching a carbon conversion efficiency of 50%, and being able to radically improve current targets of organic waste exploitation for biofuels production at the large scale.

This overarching objective will be achieved thanks to complementary activities on design, modelling, development of hardware & processes, testing and life cycle analysis of a fully integrated Heat-to-Fuel system, representative of next generations of sustainable biofuels technologies.

Our Team: