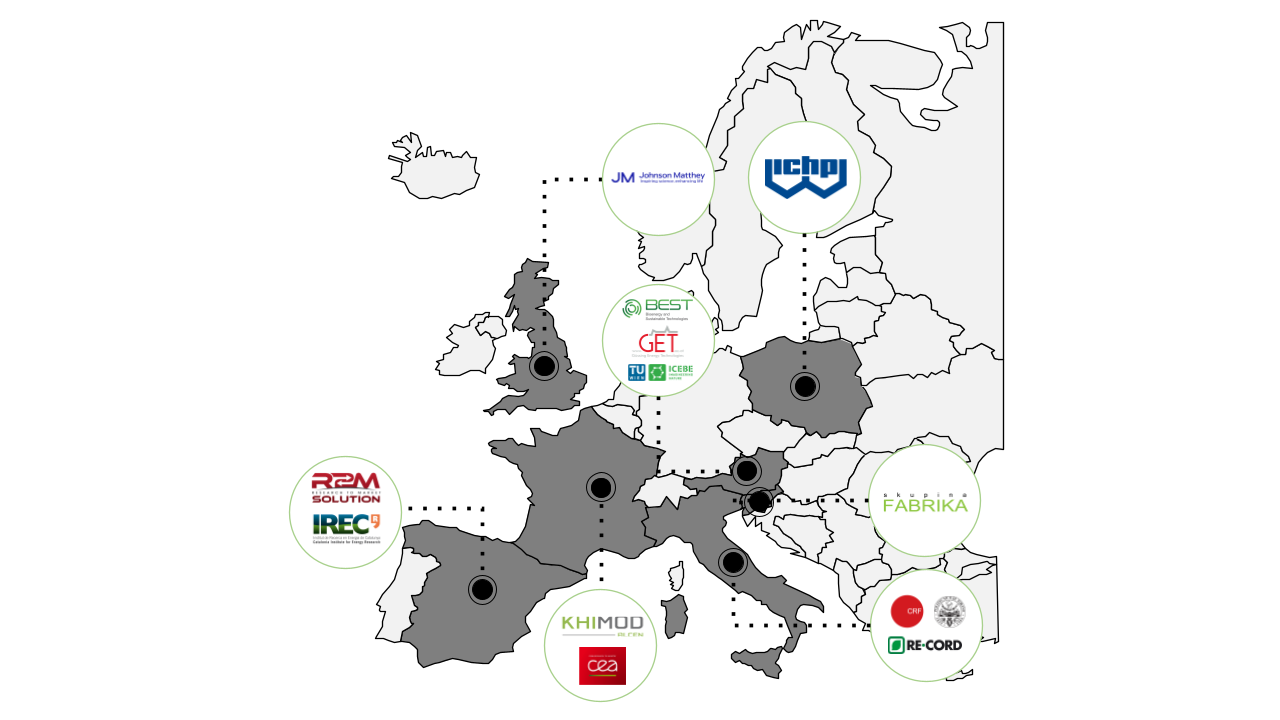

The Consortium

The consortium comprises 13 entities from 7 EU countries: 5 industrial partners (2 technical SMEs, 2 technology transfer and risk analysis SMEs, and one large component manufacturing industries); one end user from the transportation sector; 5 RTD and 2 HEA organizations to research and develop cutting-edge technologies. The consortium combines skills and expertise, bringing to the project a wide range of experts working with transdisciplinary approaches to environmental and industrial processes challenges.

The Partners

GET’s main expertise is plant engineering, project management and system combination. As Lead partner they are minimizing the risk and assuring the quality of Heat-to-Fuel. GET is furthermore easing the cooperation between the partners and all other stakeholders.

IREC works on advanced catalysts for FT synthesis and on the experimental investigation of pyrolysis/gasification kinetics.

In the project, RE-CORD will bring its expertise in the thermochemical conversion of organic waste and will investigate the hydrothermal conversion of selected feedstock and bio-based residue, and perform hydrotreating test of bio-oil.

The CEA will contribute on the design, modelling and the manufacturing of the FT structured reactor; assess the FT reactor; design both reactors APR and FT and will participate to the test at Güssing.

JM is a FTSE100 company with expertise in advanced materials and processes across a range of sustainable technologies. JM offers years of experience in a wide range of catalysts, technologies and other chemical products which are used within the petrochemical, chemical and fine chemical industries.

SF is involved in risk analysis; business case definition and development as well as implementation of developed business cases and dissemination and promotion of the project activities and results.

POLITO is involved in several activities, mainly the development of the Aqueous Phase Reforming (APR) reactor and collaboration to the design of the reactor coupling APR and Fischer-Tropsch (FT).

TU Wien is involved in the execution of gasification experiments by the use of an existing novel 100 kW DFB gasification test plant at TU Wien for a broad ranch of feedstock types

Main role of BE2020 in the project is testing of the Bi-reactional Fischer Tropsch – APR reactor in representative environment at Güssing using synthesis gas from a biomass gasifier.

IChPW competence lies in the areas of biomass feedstock specification, preparation and lab. analysis oriented on its thermochemical conversion (in Heat-to-Fuel through gasification).

In the context of Heat-to-Fuel project, KHIMOD is in charge of the APR equipment and the Fischer-Tropsch Heat Exchanger-Reactor manufacturing, aiming to demonstrate the transformation of biomass residue into biofuel (2nd generation). Based in Austria, this project is co-financed by the European Union H2020 program.

CRF will be involved into the techno-economic and environmental assessment of the developed technologies for biofuel production.

R2M focuses on achieving the maximum exploitation and impact, while safeguarding the interests of all industrial partners.